The aviation industry has always been a fascinating blend of engineering marvels and human ingenuity. Among the many intricate systems onboard an aircraft, the lavatory often goes unnoticed—until it becomes a topic of curiosity or necessity. The design and functionality of airplane toilets have evolved significantly over the decades, adapting to the constraints of space, weight, and passenger volume. This article delves into the mechanics, challenges, and innovations behind these compact yet essential facilities.

The Anatomy of an Airplane Lavatory

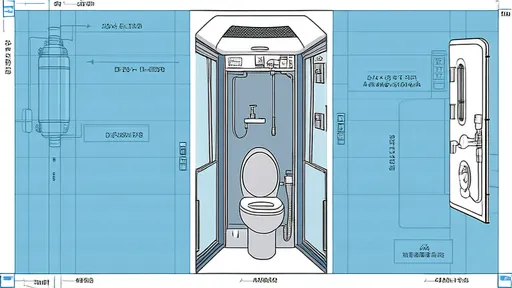

Unlike their terrestrial counterparts, airplane toilets are designed with extreme spatial efficiency in mind. Every square inch is optimized to serve its purpose without compromising safety or comfort. The typical aircraft toilet consists of a vacuum flush system, a compact sink, and a fold-down changing table for infants. The vacuum flush, a hallmark of modern aviation, uses minimal water and relies on differential air pressure to dispose of waste. This system is not only lightweight but also significantly more hygienic than older models.

The sink, often made of stainless steel or durable plastic, is designed to conserve water. A push-button or motion-activated faucet dispenses a controlled amount of water, ensuring minimal waste. The fold-down changing table, though small, is a critical feature for parents traveling with infants. These elements are packed into a space no larger than a closet, yet they manage to meet the basic needs of hundreds of passengers daily.

Engineering Challenges and Solutions

Designing a functional lavatory for an aircraft presents unique challenges. Weight is a primary concern, as every additional pound translates to higher fuel consumption. Engineers have tackled this by using lightweight materials like carbon fiber and advanced plastics. Another challenge is odor control, which is addressed through sophisticated ventilation systems that constantly circulate air and filter out unpleasant smells.

The vacuum flush system, while efficient, requires precise engineering to prevent malfunctions at high altitudes. Early systems were prone to clogs and leaks, but modern iterations are far more reliable. Additionally, the lavatory’s door mechanism is designed to be fail-safe, ensuring it can be opened from the outside in case of an emergency. These innovations highlight the meticulous attention to detail that goes into every aspect of aircraft design.

Historical Evolution of Airplane Toilets

The first airplane toilets were rudimentary at best, often consisting of little more than a bucket or a bag. As commercial air travel grew in the mid-20th century, so did the need for more sophisticated facilities. The introduction of chemical toilets in the 1950s marked a significant improvement, though they were still far from ideal. These systems used blue deodorizing liquids to mask odors, but they were heavy and required frequent servicing.

The real breakthrough came with the advent of vacuum flush technology in the 1970s. Pioneered by Boeing, this system revolutionized in-flight sanitation by drastically reducing water usage and weight. Today, vacuum toilets are the standard on virtually all commercial aircraft, a testament to their efficiency and reliability. The evolution of airplane toilets mirrors the broader advancements in aviation technology, where every component is refined for peak performance.

Passenger Experience and Etiquette

For passengers, using an airplane lavatory can be a daunting experience, especially first-time flyers. The confined space and unfamiliar mechanics can lead to awkward situations. Airlines strive to make the experience as seamless as possible with clear instructions and intuitive design. However, passenger etiquette plays a crucial role in maintaining cleanliness and functionality.

Common courtesy, such as knocking before opening the door and avoiding excessive use of toilet paper, goes a long way in ensuring a pleasant experience for everyone. Flight attendants often remind passengers to dispose of sanitary items properly, as flushing inappropriate materials can lead to costly repairs and delays. The lavatory may be small, but its impact on the overall flight experience is significant.

Future Innovations and Sustainability

As the aviation industry moves toward greater sustainability, airplane toilets are not exempt from innovation. Researchers are exploring ways to further reduce water usage and even recycle waste for use as fertilizer or energy. Some prototypes feature touchless technology, minimizing contact with surfaces to enhance hygiene. These advancements align with the broader goals of reducing the environmental footprint of air travel.

Another area of focus is accessibility. Newer aircraft models are incorporating larger lavatories to accommodate passengers with disabilities, a long-overdue improvement. These designs include grab bars, wider doors, and more space to maneuver, ensuring that air travel is inclusive for all. The future of airplane toilets is not just about functionality but also about equity and environmental responsibility.

Conclusion

The humble airplane toilet is a marvel of modern engineering, born out of necessity and refined through decades of innovation. From its early days as a simple bucket to today’s high-tech vacuum systems, it has come a long way. As air travel continues to evolve, so too will the designs and functionalities of these essential facilities. The next time you find yourself in an aircraft lavatory, take a moment to appreciate the ingenuity that makes it all possible.

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025

By /Aug 6, 2025